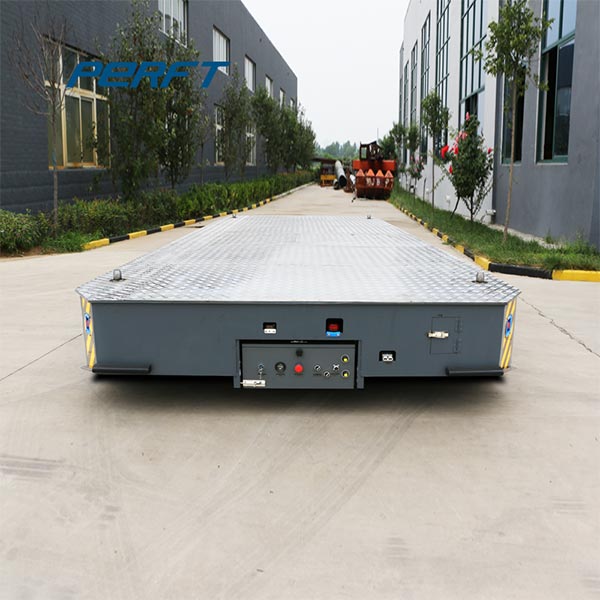

Trackless Transfer Trolley-Material Handling Solution

Series: BWP Trackless Transfer Vehicle

Transport speed: 0-30m/min

Power supply mode: track power supply/battery power supply/cable power supply

Application range: metallurgy, coal, electromechanical, heavy industry and other industries

Handling objects: large molds, aluminum coils, steel coils, steel, steel ingots, boilers, casting modules

Trackless Transfer Trolley: A Revolutionary Material Handling Solution

In today’s manufacturing industry, the efficiency of material handling systems plays a crucial role in increasing production output. Industrial trolleys, conveyors, and other material handling equipment are used to transport goods within a facility. However, the traditional trolleys have limitations in terms of flexibility and adaptability. This is where trackless transfer trolleys come into the picture.

What are trackless transfer trolleys?

Trackless transfer trolleys are a new type of material handling equipment that uses battery-powered motors to transport goods in a factory setting. Unlike traditional trolleys that are restricted to travel on designated tracks, trackless transfer trolleys can move in any direction on a plant floor. They have sensors that detect obstacles and automatically stop the trolley to prevent accidents. These trolleys are ideal for transportation within a factory for high-volume production processes.

What are the benefits of using trackless transfer trolleys?

1. Flexibility: The biggest advantage of using trackless transfer trolleys is their flexibility. They are not bound by tracks and can move in any direction on a plant floor. This makes them easily adaptable to various production processes and allows for customization according to specific needs.

2. Safety: Trackless transfer trolleys come with state-of-the-art sensors that detect obstacles and prevent collisions. They are designed to maneuver around obstacles and ensure maximum safety for the operators and products they carry.

3. Increased efficiency: With the ability to move in any direction and carry more goods, trackless transfer trolleys help increase the overall efficiency of material handling systems. They can transport materials faster and with fewer delays, which ultimately leads to higher production output and faster turnaround times.

4. Cost-effective: Using trackless transfer trolleys can save companies money by reducing the need for complex network systems found in traditional trolleys. They can carry a variety of items, including oversized and heavy items, without the need for extensive installation requirements.

5. Easy to Operate: Trackless transfer trolleys can be easily operated with minimal training. They have user-friendly interfaces, which can be programmed to ensure a smoother material handling process.

In conclusion, trackless transfer trolleys are a revolutionary material handling solution that provides a flexible, efficient, and cost-effective method of transporting materials. They offer an excellent alternative to traditional material handling equipment and provide manufacturers with a competitive edge in a highly competitive market. With the rising demand for automated solutions, trackless transfer trolleys are set to become the future of material handling systems.