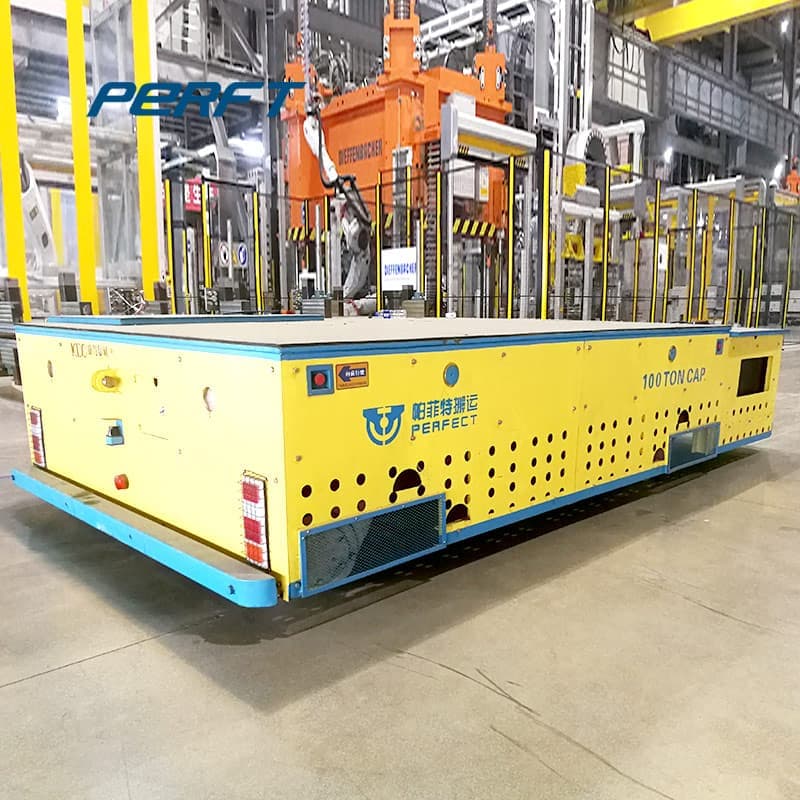

Trackless flatbed truck with heavy load of 20 tons

On the client’s side, the items that carry large objects are transported back and forth in the workshop; because of the high frequency of use, forklifts cannot carry large objects, so trackless flatbed trucks are used.

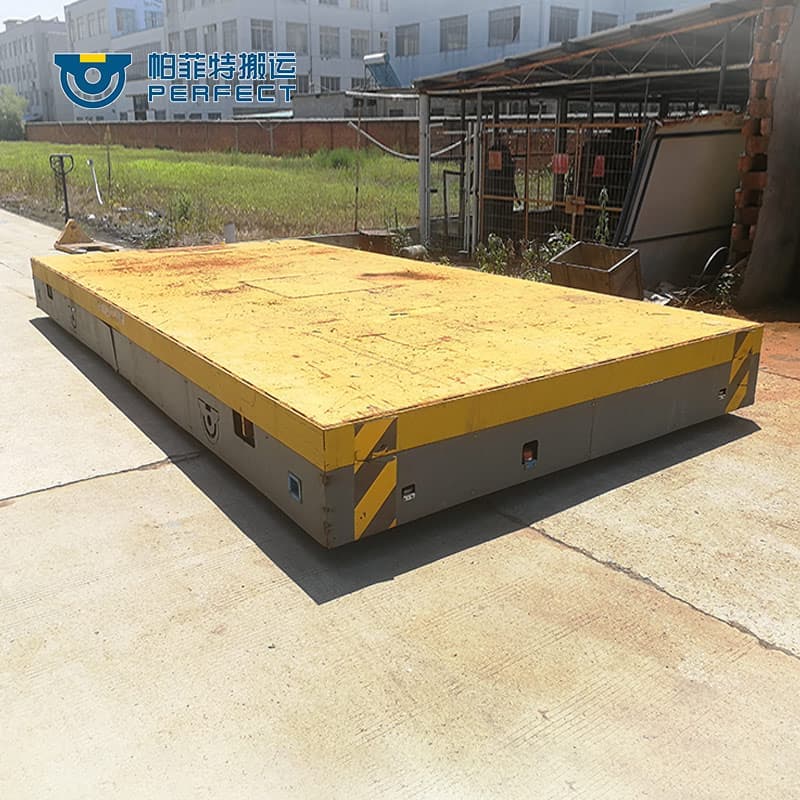

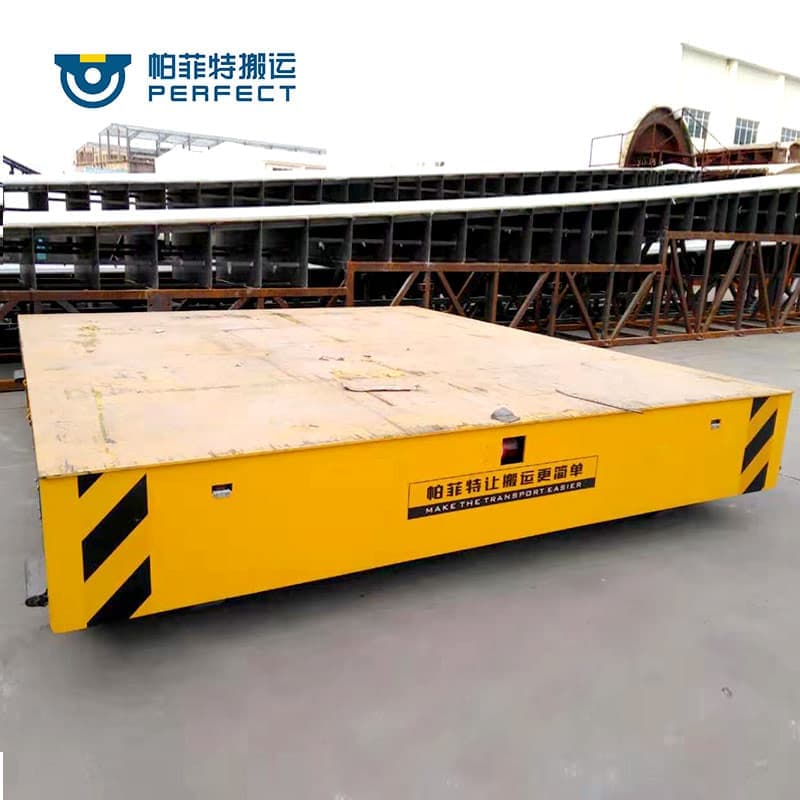

Description:The trackless handling vehicle is an alternative transfer cart for rail transfer cars. It overcomes many inconveniences of rail-type electric transfer carts. The trackless electric transfer carts can finish free-turning without the rail in the workshop and workshop. There is no need to lay rails, so it does not affect traffic, does not hinder production, and the flat car is more flexible, the operation is more humanized.

Feature:1. The safety requirements of the trackless flat car are high: most of the molds are heavy-duty workpieces, and the safety of personnel and articles must be ensured during transportation. No accidents such as bumps or dumping may occur.

2, trackless flat car heavy load capacity is strong: the weight of the mold is large, and some weight can reach hundreds of tons.

3. The trackless flat car runs flexibly: the mold has large elasticity, large volume, and large space during movement.

4, the trackless flat car should be a low table: the height limit of the die press, the mold transport height cannot be too high.

5, the trackless flat car to operate easily: the molding stamper is not just a stamper, it will be replaced by many molds.

6, the operation of the trackless flat car is not limited: the mold occupies more space in the workshop, and the transportation equipment should be able to transfer the mold anytime and anywhere.

7. Trackless flat car protection workshop floor: Since the mold is generally heavy, the pressure of each wheel is relatively heavy, so the wheel material is very strong and will not cause damage to the ground.

Applications:

The trackless handling vehicle is mainly use in heavy industry, light industry, machinery, petroleum, metallurgy, mining, chemical, ship, etc., can handle steel coils, aluminum coils, galvanized coils, transformers, cable reels, castings, motors, containers, compartments, containers, pressure vessels, etc.