steel ladle transfer car

The steel ladle transfer car is an essential equipment in the steelmaking industry. It is responsible for transporting molten steel from the steelmaking furnace to the casting area. To meet the high temperature and heavy load requirements, the steel ladle transfer car is designed with high-quality materials and a range of advanced technologies.

The steel ladle transfer car is an essential equipment in the steelmaking industry. It is responsible for transporting molten steel from the steelmaking furnace to the casting area. To meet the high temperature and heavy load requirements, the steel ladle transfer car is designed with high-quality materials and a range of advanced technologies.

One of the main advantages of the steel ladle transfer car is its ability to withstand high temperatures. It is equipped with heat-resistant materials, which enable it to operate in extreme temperatures of up to 2000°C. Additionally, the car is designed with an insulation layer to minimize heat transfer from the molten steel.

Another key feature of the steel ladle transfer car is its strong load-bearing capacity. The car is designed to accommodate heavy steel ladles weighing up to 500 tons. This capacity is achieved through the use of high-strength materials, such as high-strength steel and high-quality cast iron.

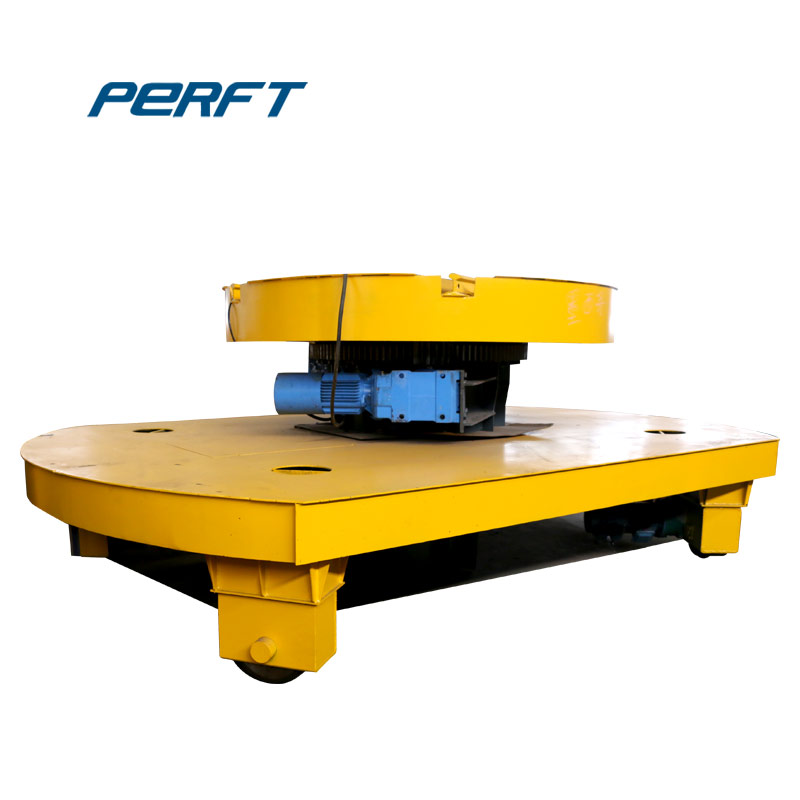

To ensure smooth and efficient operation, the steel ladle transfer car is equipped with a dual-drive system. The double-drive design ensures maximum stability and control during transport, allowing the car to handle steel ladles easily and securely.

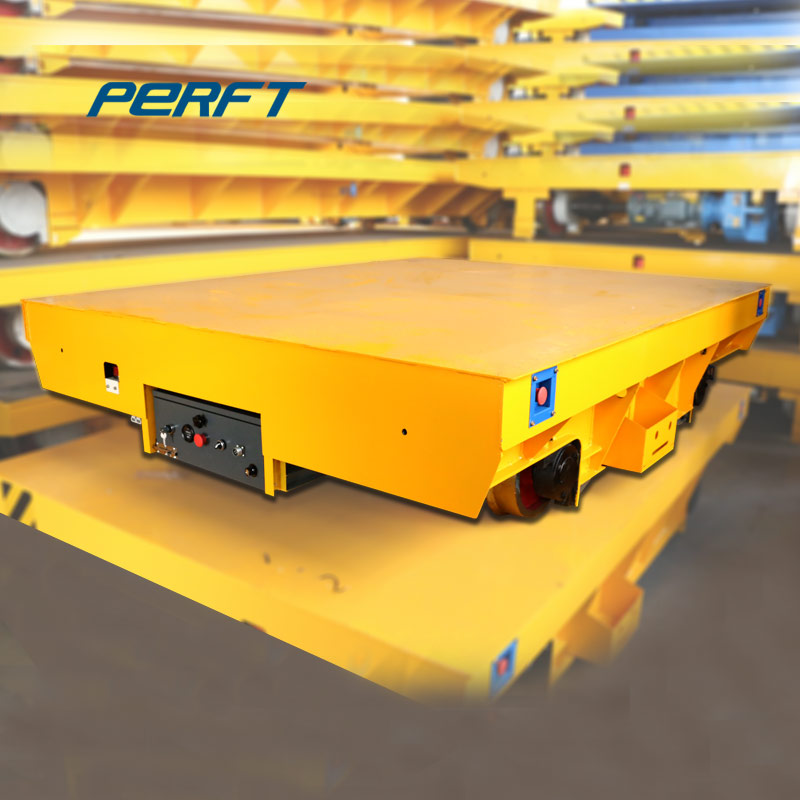

Finally, the steel ladle transfer car is designed with a range of safety features to prevent accidents and injuries. For example, it is equipped with emergency stop buttons, anti-collision systems, and limit switches to prevent overloading and collisions.

Overall, the steel ladle transfer car is an essential and reliable piece of equipment in the steelmaking industry. Its ability to withstand extreme temperatures, strong load-bearing capacity, double-drive system, and safety features make it an ideal solution for steelmaking plants.