New Energy Die Transporter: A Greener, More Flexible Solution for the Manufacturing Industry

In recent years, the manufacturing industry has been making strides towards reducing its carbon footprint and adopting more sustainable practices. One area where this has been particularly evident is in the transportation of dies or molds used in the production process. Traditionally, these have been moved around using diesel-powered truck fleets. However, more and more businesses are making the switch to new energy die transporters, which offer a range of advantages over their fossil fuel counterparts.

New Energy Die Transporter: A Greener, More Flexible Solution for the Manufacturing Industry

In recent years, the manufacturing industry has been making strides towards reducing its carbon footprint and adopting more sustainable practices. One area where this has been particularly evident is in the transportation of dies or molds used in the production process. Traditionally, these have been moved around using diesel-powered truck fleets. However, more and more businesses are making the switch to new energy die transporters, which offer a range of advantages over their fossil fuel counterparts.

New energy die transporters is their lower environmental impact. These vehicles run on electricity, which means no harmful emissions are released into the atmosphere. This is an especially important consideration for businesses looking to reduce their carbon footprint and meet sustainability targets.

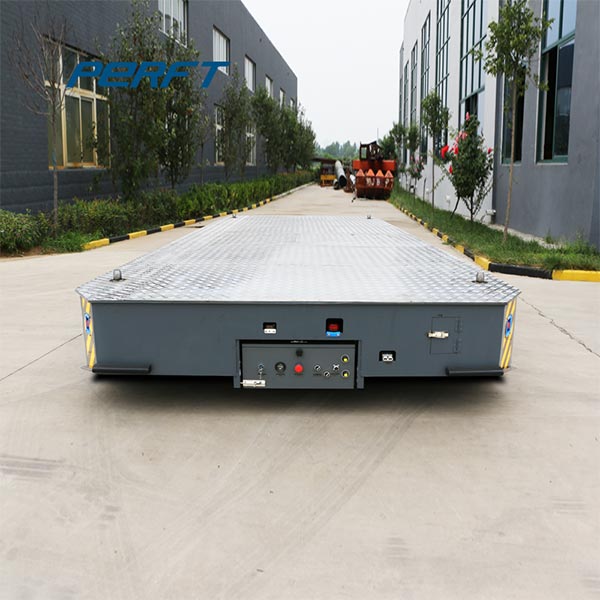

New energy die transporters is their flexibility. They can be used in a range of settings, including indoors within a mold workshop environment. These high-speed mold transporters can move quickly around a production facility, providing cost-saving benefits in addition to improving productivity and efficiency. Additionally, for facilities with different power supply requirements, these vehicles can be equipped with a variety of power options including AC or DC transformers and battery packs, allowing for greater flexibility when it comes to servicing customer needs.

New energy die transporters can also provide significant cost savings for businesses. With no fuel costs to worry about, these vehicles can help to reduce overheads. And because they are designed to be low-maintenance, they don’t require as much upkeep and servicing as traditional diesel-powered trucks.

New energy die transporters are an excellent choice for businesses looking to reduce their carbon footprint, improve productivity and efficiency, and save costs in the manufacturing process. With their flexible design and a range of power supply options, these vehicles are poised to become the future of mold transport.