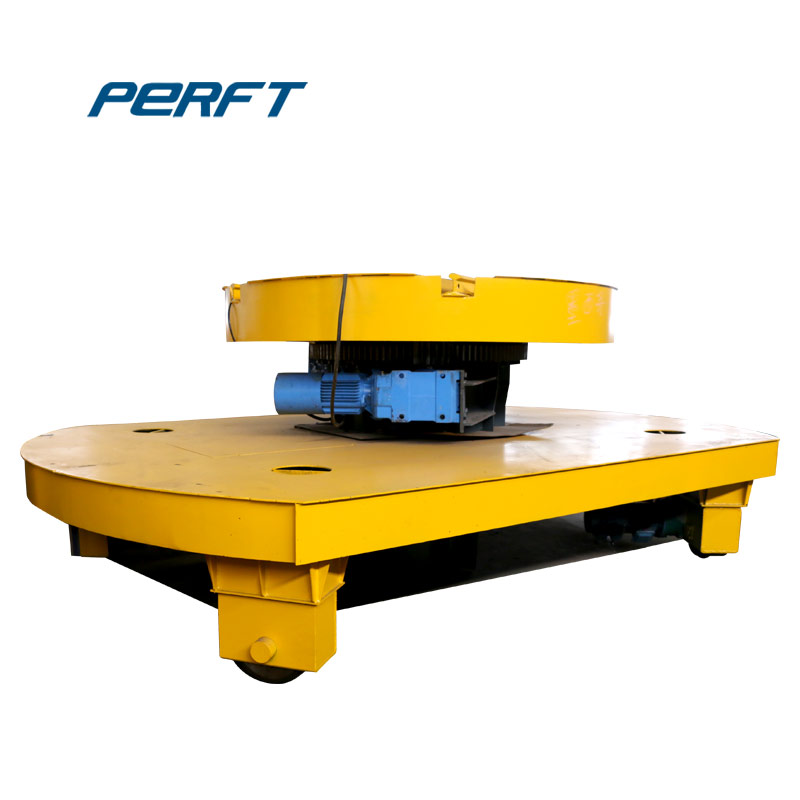

Heavy Duty Steel Ladle Transfer Car For Casting Plant

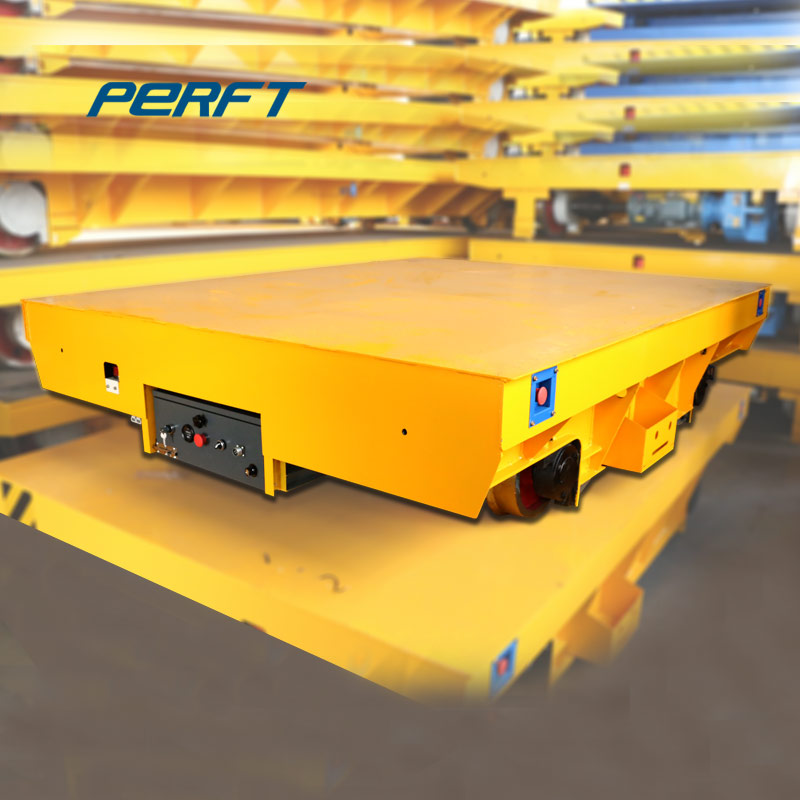

The heavy-duty steel ladle transfer car is an essential component in the steelmaking process. Its role is to transport molten steel safely and efficiently from one location to another within the facility. To ensure maximum safety for workers and the integrity of the product, modern ladle transfer cars are equipped with several features that make them reliable and efficient.

Heavy Duty Steel Ladle Transfer Car For Casting Plant

The heavy-duty steel ladle transfer car is an essential component in the steelmaking process. Its role is to transport molten steel safely and efficiently from one location to another within the facility. To ensure maximum safety for workers and the integrity of the product, modern ladle transfer cars are equipped with several features that make them reliable and efficient.

One of the most critical features of a heavy-duty steel ladle transfer car is the use of high-temperature insulation material. The material ensures that the car is protected from the high temperatures of molten steel and other materials, which are often above 1000°C. This helps keep the operator and other personnel safe, as well as the transfer car in good condition.

Another essential feature is the explosion-proof electric motor. The motor is specifically designed to operate in hazardous environments, such as those with combustible gases or vapors. This motor prevents the ignition of these gases, thereby providing an additional layer of safety for the worker.

The ladle transfer car is also equipped with remote control, further improving its safety and efficiency. This feature enables the operator to control the car from a safe distance, reducing the risk of accidents or injuries. It also helps to ensure that the car accurately follows the intended route, avoiding damages to interiors or other parts of the facility.

In conclusion, heavy-duty steel ladle transfer cars are essential in the steelmaking process. The use of high-temperature insulation material, explosion-proof electric motors, remote control, and other features make these machines safe and efficient for the workers and the facility.