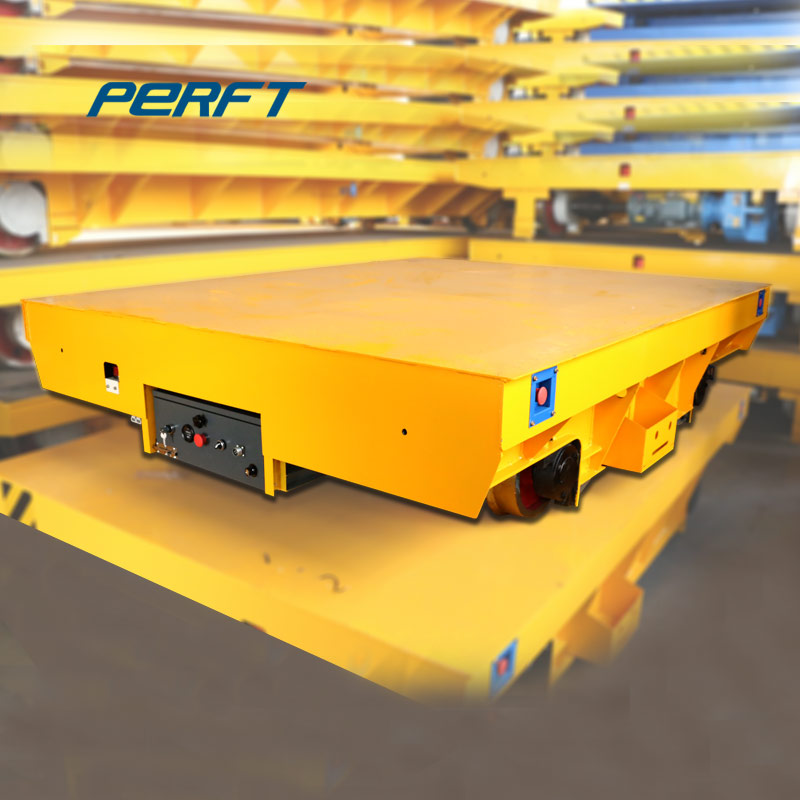

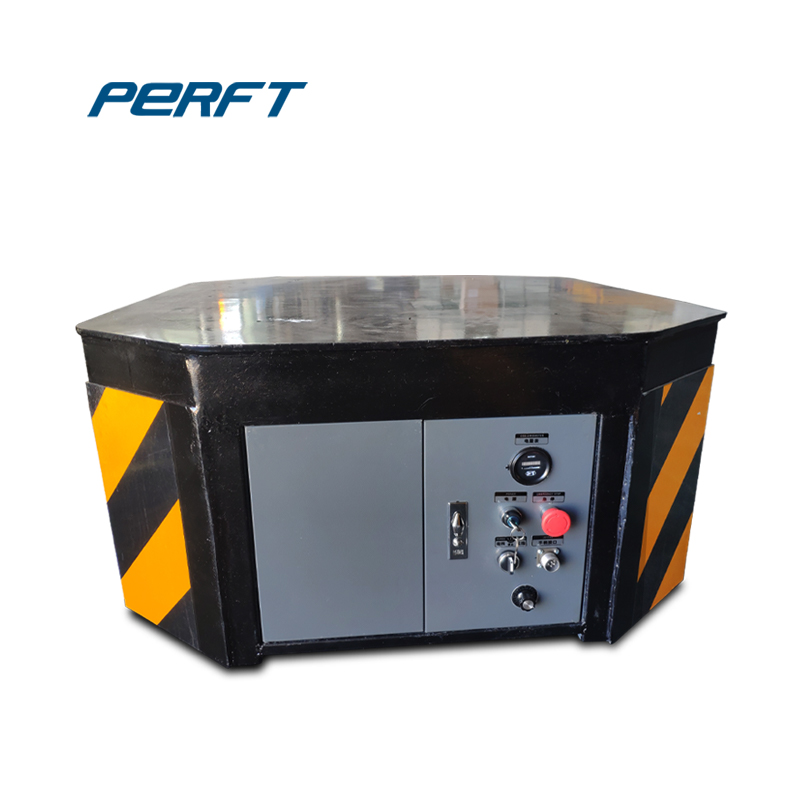

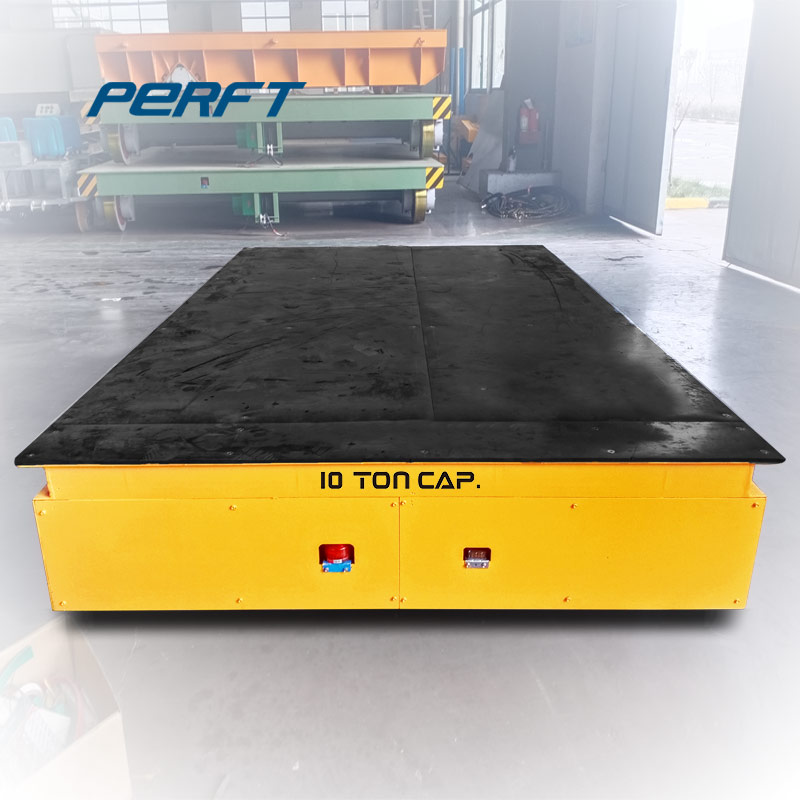

General steelworks handling equipment

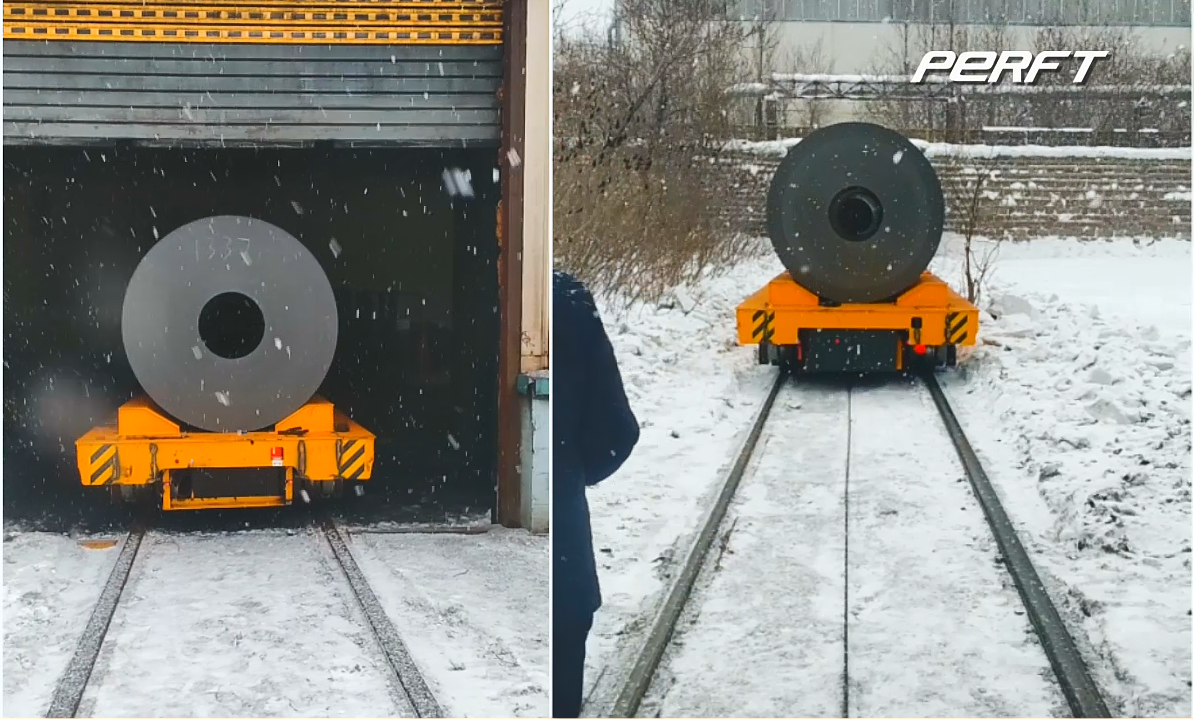

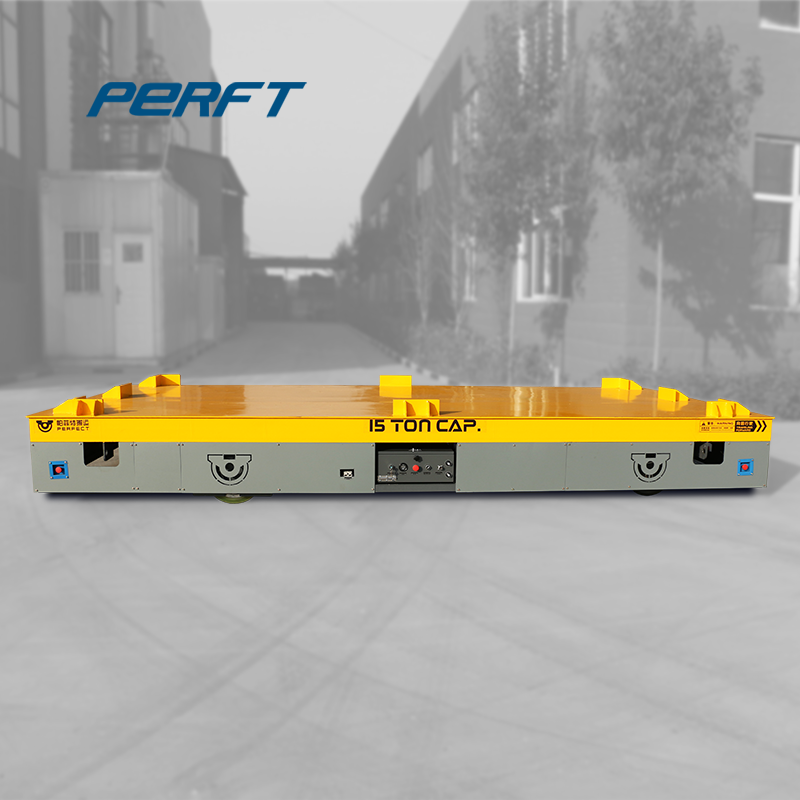

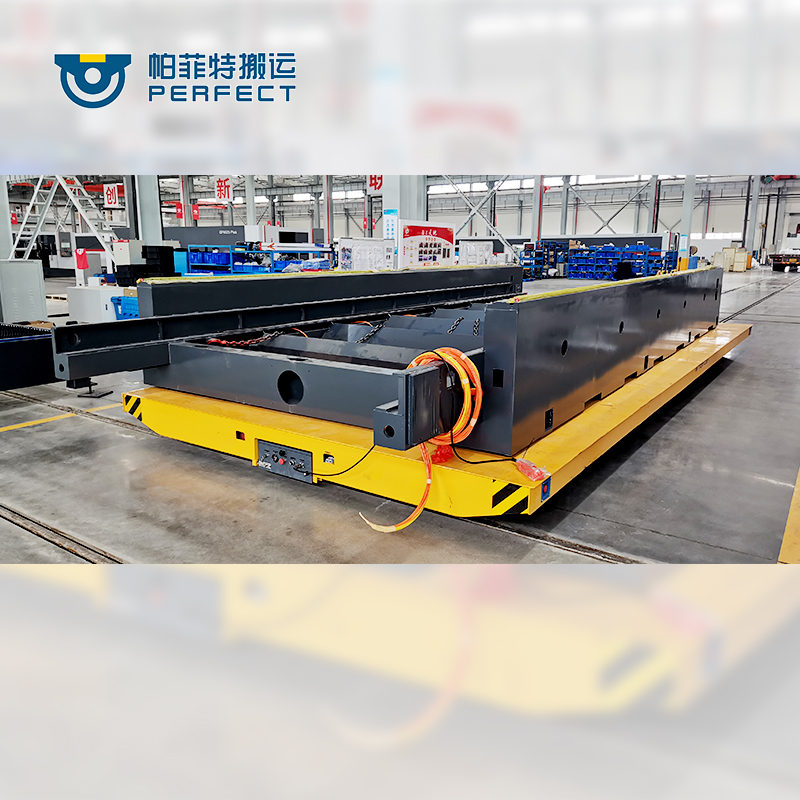

The ladle truck is also known as a steel handling truck. It is a kind of electric flat car specially developed for steelmaking plants to transport high temperature ladles. Because of the high temperature of the steel and slag, the use of ordinary transfer electric In order to avoid accidents such as steel and slag bursting and causing burns to employees, the manufacturer has developed a ladle transfer vehicle, which can be operated remotely. The ladle transfer vehicle can be operated remotely, with free control of the running speed, and running on rails to avoid steel splashes and high temperature burns and to ensure the health of employees.

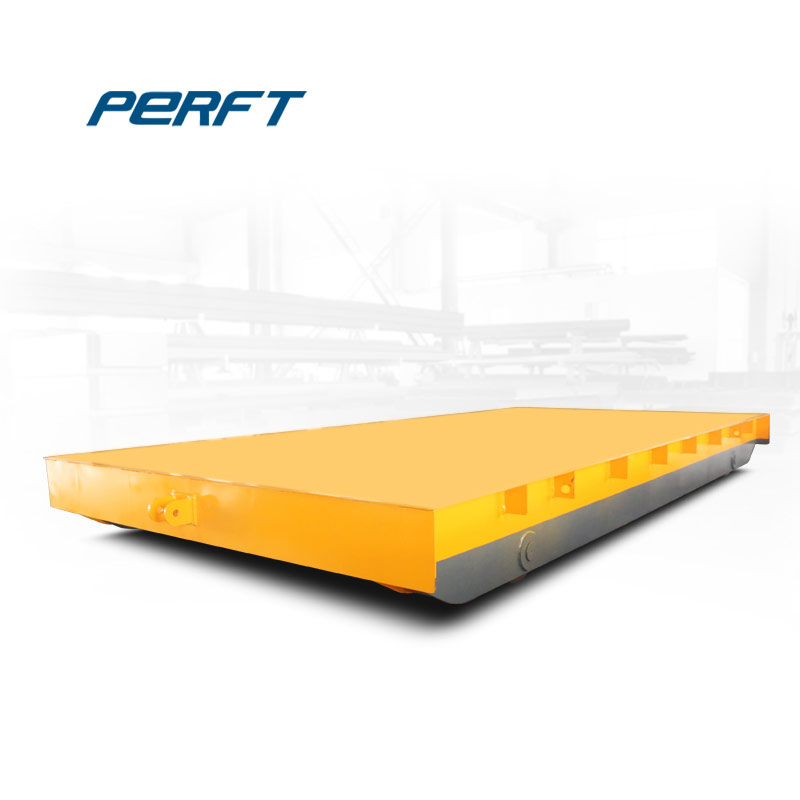

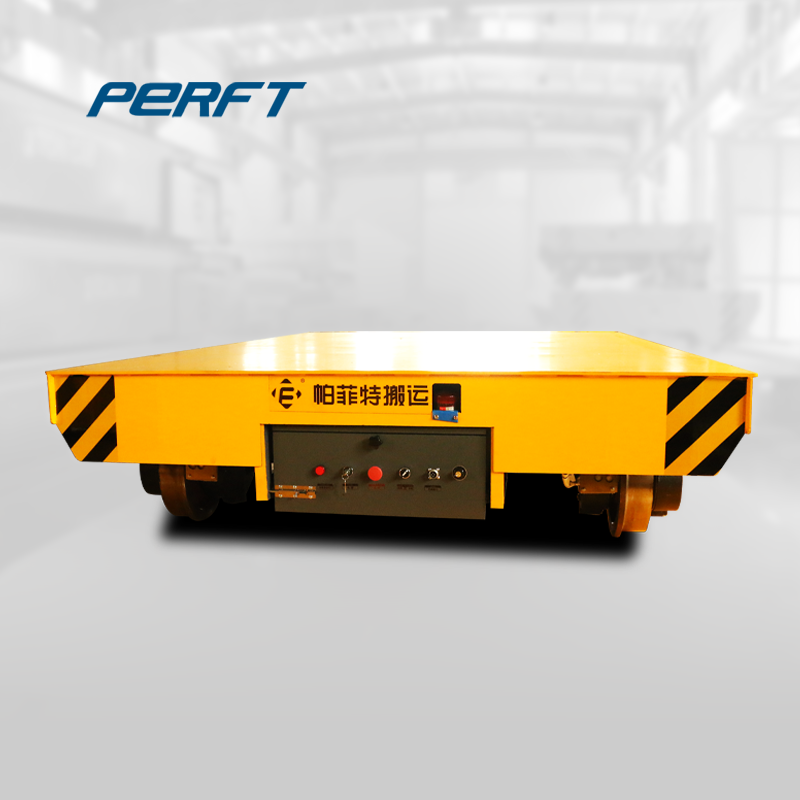

General steelworks handling equipment

The ladle truck is also known as a steel handling truck. It is a kind of electric flat car specially developed for steelmaking plants to transport high temperature ladles. Because of the high temperature of the steel and slag, the use of ordinary transfer electric In order to avoid accidents such as steel and slag bursting and causing burns to employees, the manufacturer has developed a ladle transfer vehicle, which can be operated remotely. The ladle transfer vehicle can be operated remotely, with free control of the running speed, and running on rails to avoid steel splashes and high temperature burns and to ensure the health of employees.

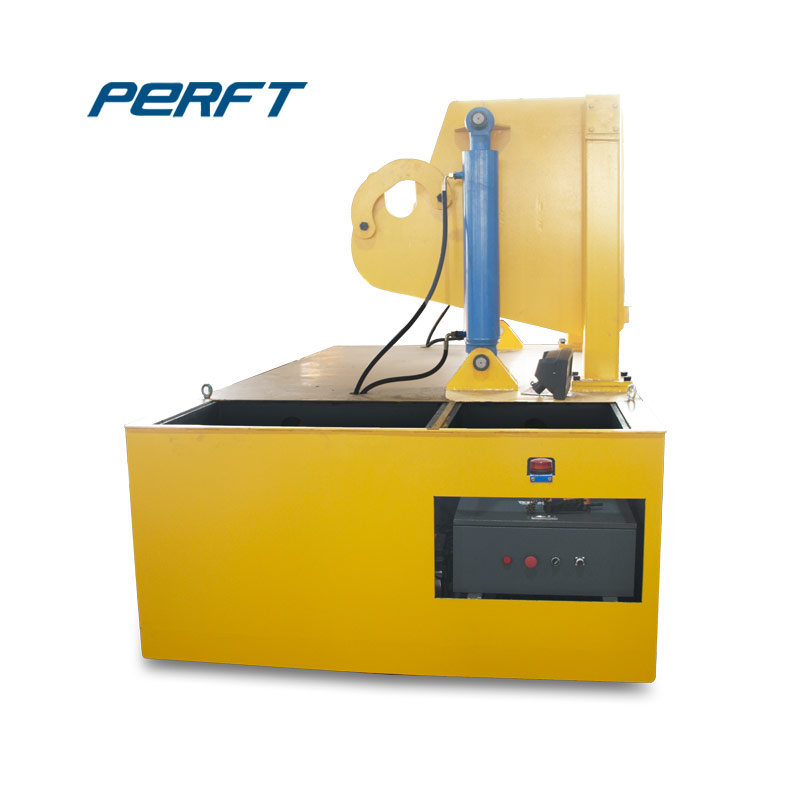

The ladle transfer car has higher requirements for high temperature, higher requirements for the car body material, transmission system and electrical control than ordinary transfer cars. In order to reduce inertia and spillage of steel or slag, the traction motor of the The traction motor of the ladle transfer vehicle is designed for slow start and slow stop; the vehicle is equipped with heat insulation to prevent the ladle body from being exposed to high temperature radiation. The drive of the ladle transfer vehicle is divided into electric single drive and electric double drive, but in order to better ensure the transport of the steel, a double drive system is generally used, so that if one system fails, the other can also ensure The other system is able to complete a process cycle if one system fails.