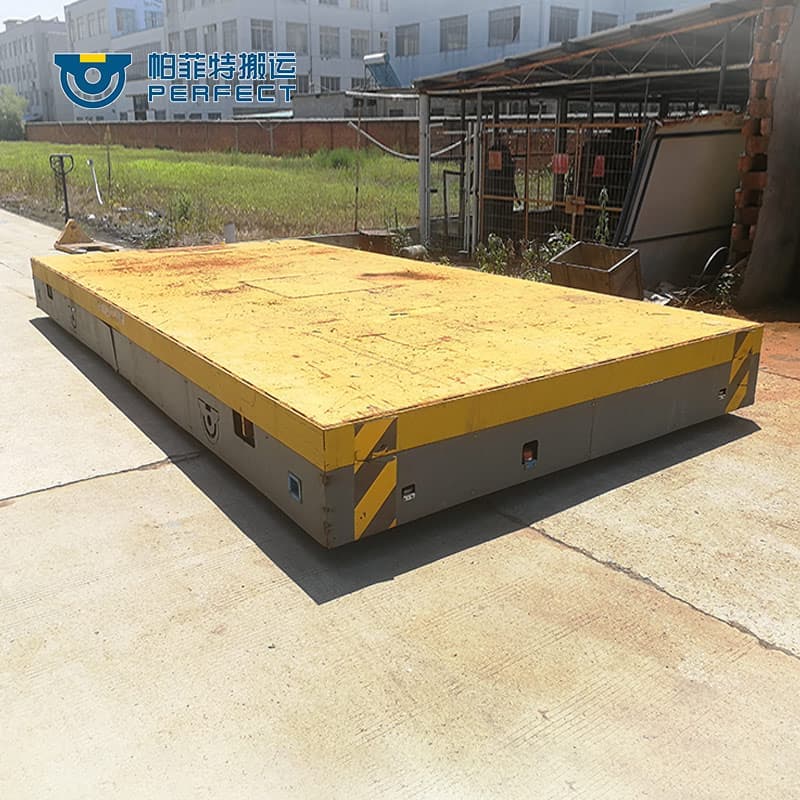

BWP-20 TONS trackless transfer cars

Perfte’s trackless electric flat car, it is a kind of wheeled handling equipment that can be manually manipulated and steered freely. The car relies on the ground track, does not damage the infrastructure, can walk freely on the ground, and is free to turn without space and ground restrictions, and can change the walking direction and route at any time.

BWP-20 TONS trackless transfer cars

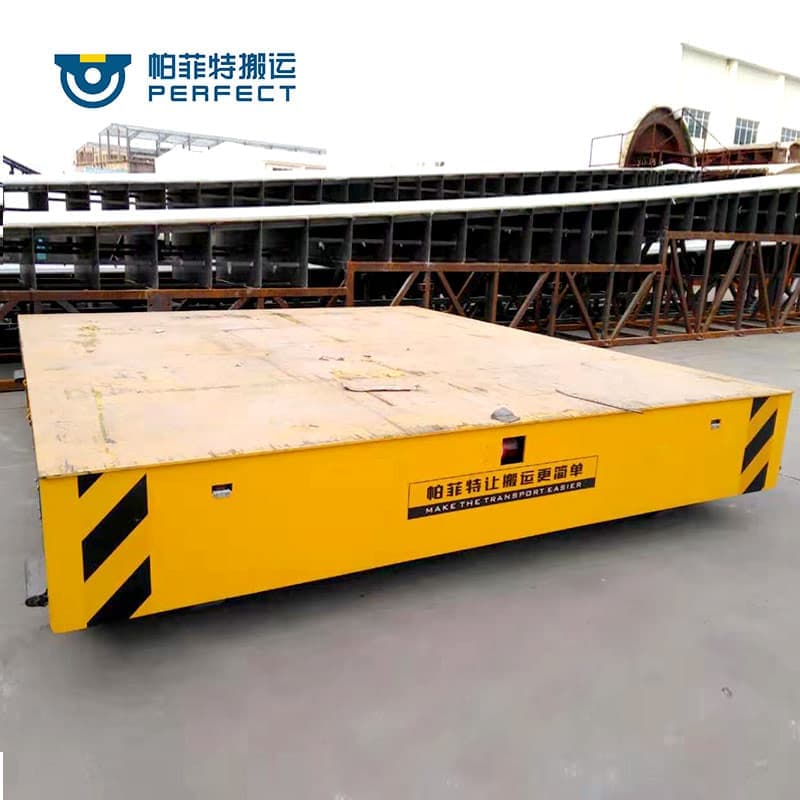

Xinxiang Perfte Co., Ltd. is a professional manufacturer of electric flat cars. Trackless transfer cars are one of them. It is mainly made of polyurethane. Casting polyurethane is a mixture of two liquid macromolecular compounds as a prepolymer, and the other is a The curing agent is used to fully stir the two liquid macromolecular compounds manually or mechanically.

Then inject it into the corresponding special mold, and after vulcanization and curing, the required wheel shape can be obtained. It is classified according to its chemical composition. Polyurethane elastomers are mainly divided into polyester type and polyether type. Polyurethane outer ring is covered. The components of various mechanical wheels, the electric rubber wheeled car has the following characteristics:

1. High wear resistance.

2. It has high elastic modulus, high tensile strength and high elongation, so it has extremely high toughness and durability.

3. Compared with ordinary elastomers, the bearing capacity is larger.

4. Hardness and impact resistance: By changing the composition ratio of the prepolymer, various hardnesses can be obtained. In addition to superior mechanical properties, it also has strong environmental adaptability.

Its excellent anti-corrosion performance, the stability in organic solvents is obviously better than that of ordinary hydroxy rubber materials, and it is resistant to oil, acid and alkali.

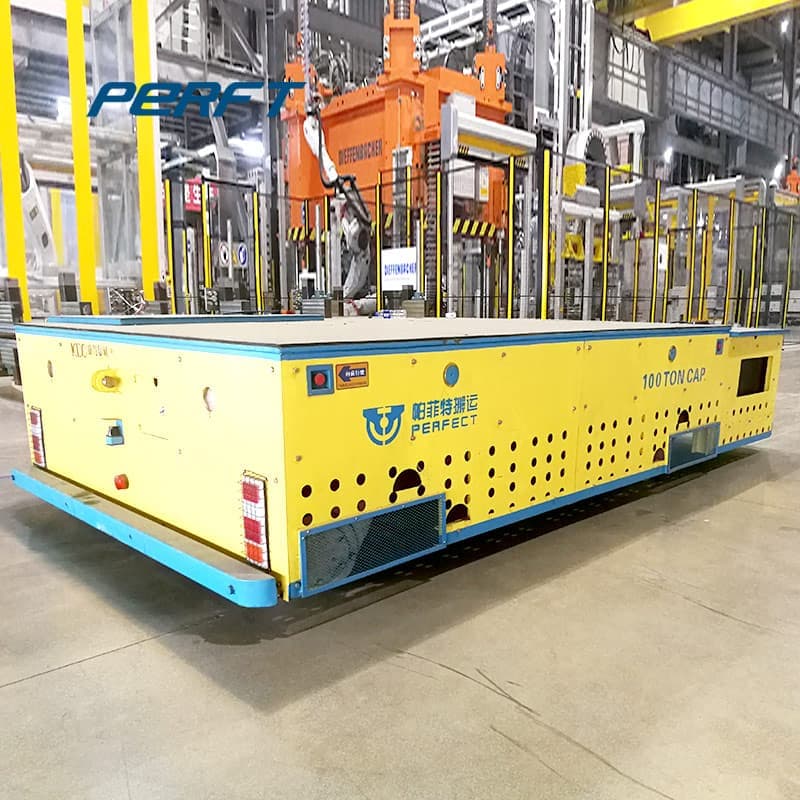

| The heavy load battery powered transfer vehicle is made up of the battery as the power source of the series of flat cars. It supplies power to the flat car. The DC current flows into the electric box, and the electric box is supplied to the operating system and the motor. The control unit or the remote control controls the motor. Reverse, stop, etc., and then control the forward, backward, start, and stop of the flat car. Applications: Mold workshop, underground mine, engineering, aerospace, coal, nuclear energy, water conservancy, etc. Advantage: The Heavy load battery powered transfer vehicle have safety and maneuverability, the operation is not limited by distance, the speed is adjustable, and the flat-car DC motor has the advantages of stable starting, large starting torque, small impact on the reducer, low voltage and long service life. The requirements for track laying are not high, and it is suitable for occasions with low frequency and long distance transportation. The heavy load battery powered transfer vehicle adopts a DC motor, which is suitable for frequent use and has higher safety and maneuverability. It can meet the transportation environment with high frequency of use and can be equipped with hard-tooth surface reducer, which makes the maintenance of flat car later simple. The heavy load battery powered transfer vehicle is relatively simple, easy to repair, easy to disassemble, strong carrying capacity, long service life, low requirements for track laying, low cost, suitable for harsh environments, high temperature environments and other occasions. Battery operated motorized material transfer carts on rail is suitable for various use environments, and can work in indoor, outdoor, inflammable and explosive environments, and can also add hydraulic devices, buffer devices, etc. on the flat car. The operation is simple. When the transportation distance is long, the on-board operation console can be added to the flat car to meet the long-distance transportation of the customer and realize the humanized design. The heavy load battery powered transfer vehicle can add PLC control system, automatic rail car, greatly increase work efficiency. |