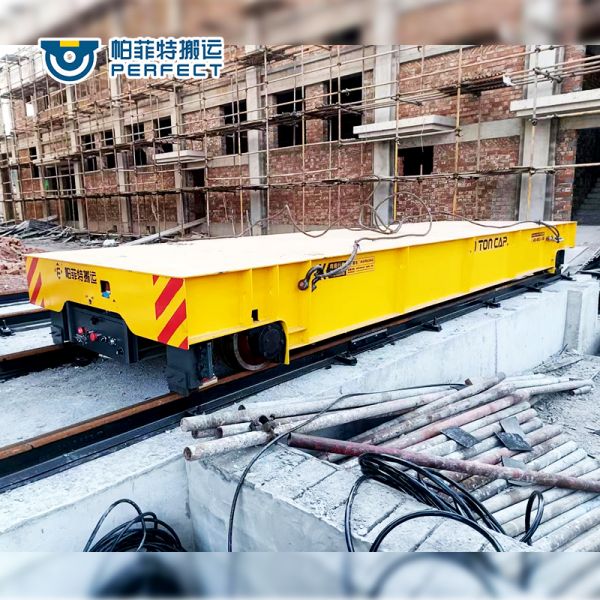

Anti Heat Electric Transfer Cart In Foundry Workshop

Features of Anti Heat Electric Transfer Cart in Foundry Workshops

Extreme heat resistance: Safely handles high temperatures.

Enhanced safety: Heat-resistant insulation, emergency controls.

Efficient handling: Streamlines workflow, reduces risks.

Customizable Design: Tailored for foundry needs.

Molten metal transport: Safe furnace-to-mold transfer.

Optimized mold handling: Enhances casting processes.

Heat-sensitive components: Efficient transport in extreme conditions.

Foundry workshops are at the heart of industries that deal with extreme heat and challenging material handling. In this demanding environment, efficiency, safety, and precise operations are paramount. Enter the game-changing solution of anti heat electric transfer carts, designed to revolutionize material transport within foundry workshops. As a purchaser in this industry, you’re about to explore how Perfect electric transfer carts can reshape foundry operations.

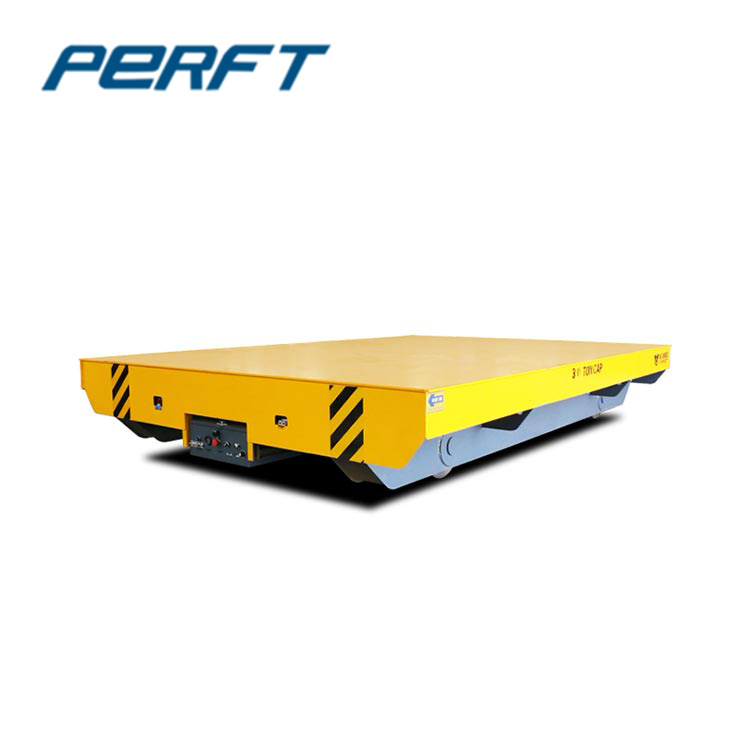

Why Choose Perfect Anti Heat Electric Transfer Carts

- Extreme heat resistance: These carts are designed to function without issue in extremely hot weather, facilitating the safe transfer of products that would be difficult to move otherwise.

- Improved safety: In situations like foundries, safety is crucial. The anti-heat electric transfer carts from Perfect are equipped with security features including heat-resistant insulation and emergency stop controls.

- Efficiency in cargo handling: By streamlining cargo transfer and eliminating manual labor and accident risk, these carts improve overall efficiency.

- Customizable design: Anti Heat Electric Transfer Carts’ load capacities, dimensions, and extra features like tilting platforms can all be modified to meet particular foundry needs.

Traditional Carts VS Anti Heat Electric Transfer Carts

|

Features |

Traditional Carts | Anti Heat Electric Transfer Carts |

| Heat Resistance | Limited capacity for extreme heat | Engineered for seamless high-temperature use |

| Safety Measures | Basic safety measures | Heat-resistant insulation, emergency stops |

| Material Handling | Manual labor-intensive | Efficient material transport, reducing risk |

| Customization | Limited adaptability | Tailored design for specific foundry needs |

| Workflow Impact | Potential bottlenecks and safety issues |

Smooth workflow, reduced downtime |

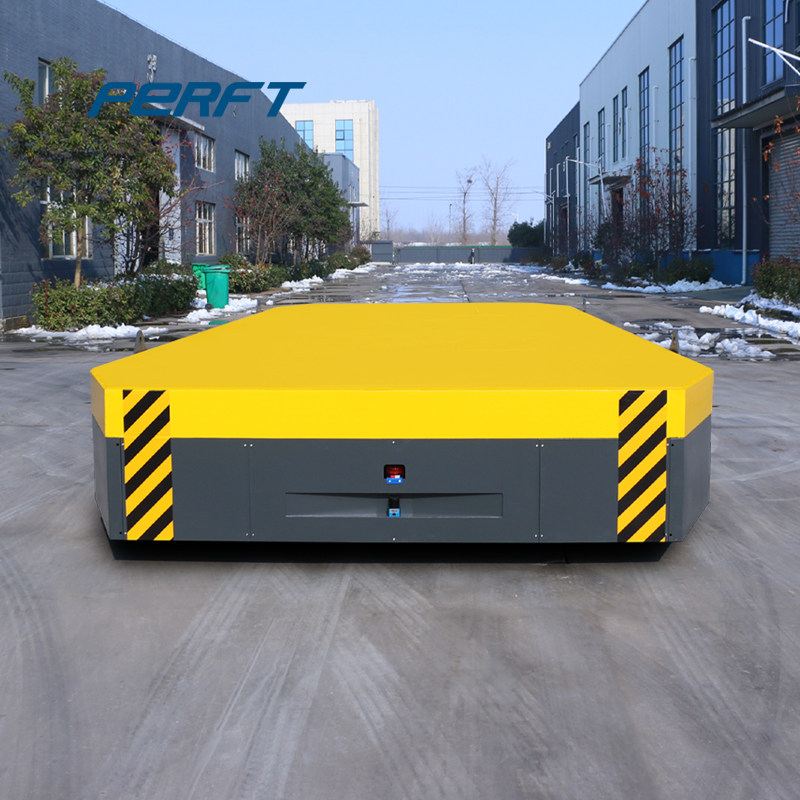

How Anti Heat Electric Transfer Carts Transform Foundry Workshops

- Transport of molten metal: These carts are excellent at moving molten metal from furnaces to molds safely while lowering the possibility of spills and mishaps.

- Mold handling: Anti Heat Electric Transfer Carts simplify the movement of molds, optimizing the mold casting procedure and raising general production.

- Transport of heat-sensitive components: These carts are effective for moving delicate components that may be harmed by high heat.

The solutions used in foundry workshops are also changing to meet their needs. This advancement is embodied in Perfect anti heat electric transfer carts, which provide a risk-free, effective, and optimum method of moving items under intense heat. You are investing in more than just equipment when you incorporate these carts into your foundry operations; you are also investing in improved safety, higher productivity, and a competitive advantage.

Solutions that can endure intense heat and improve operational efficiency are required in the realm of foundry workshops. Anti heat electric transfer carts from Perfect provide a seamless manner to handle hot metal, molds, and heat-sensitive parts in response to this demand. These carts are ready to revolutionize the way foundry workshops are run thanks to their improved safety measures, adaptable designs, and effective material transfer. Use Perfect anti heat electric transfer carts to embrace the future of material handling and see the transformation for yourself.