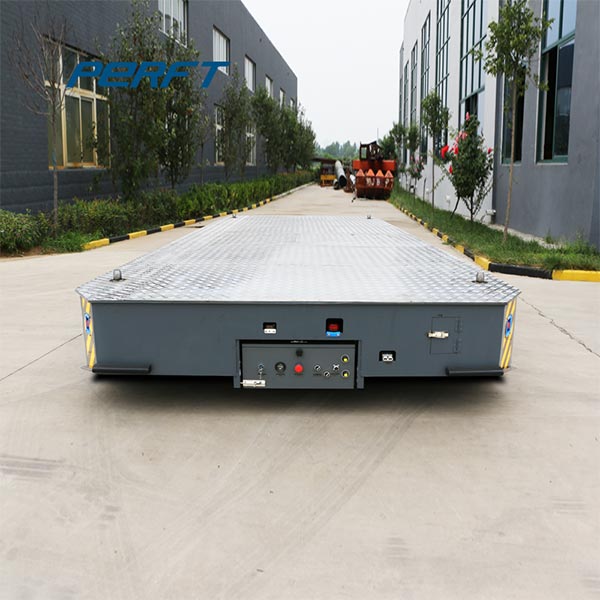

5T Falt wagon to transport injection molds for warehouse use

The biggest advantage of the electric trackless transfer car is that it gets rid of the restrictions of the ground track, increases the effective use area of the workshop, and improves the utilization rate of the workshop area; the trackless transfer car can be turned and traveled at will by borrowing the logistics channel of the workshop, especially suitable for stamping workshop molds and cross transfer of stamped sheets.

Product Introduction

The injection molding tool carts for molds is designed for die and mold handling, it is an electric transport cart which can be powered by a battery, low voltage rail, cable drum, towed cable. There are two types of electric transfer carts, rail guided and freely movable. Whether you opt for a rail-guided or a freely trackless movable solution, all can be met with a customized solution.

Depending on the size of the die and mold, you can choose the size and load capacity as your demands.

Advantages of the injection molding tool carts

Safety and flexibility;

High efficiency and stable start;

Long lifetime and durable, at least 20 years of a lifetime;

Simple structure;

Using frequency;

Easy maintenance and operation

Environmental protection

Applications of the injection molding tool carts :

Die handling;

Portable machine base;

Assembly mount;

Metal coil transporter;

Heavy equipment transporter with lift deck;

Structural steel transporter;

Shuttle cart for the pipe;

Pre-cast concrete production trolleys;

The portable base for jib arm with a spreader beam.

Custom Options of the injection molding tool carts:

Flat decks or fixtures customized for specific loads.

Custom deck configurations including built-in scales and lift/tilt/rotate capabilities.

Track or trackless, non-guided steering. Alternative drive and steering systems including gear reducer axle drives and individually-controlled drive wheels.

Fixed or variable speeds with forwarding/reverse function.

Drives with acceleration/deceleration capabilities.

Variety of operator control systems including fixed user interface, pendant control on coil cord, and radio-controlled remote operation.

Safety features including horns, flashing lights, e-stops, bumpers, and collision avoidance systems.